How Technology Solutions Can Revolutionize Manufacturing Businesses

Manufacturing is undergoing a digital revolution, reshaping how businesses operate, innovate, and serve their customers. Breakthroughs in technology are offering unprecedented opportunities for growth and efficiency across various sectors. These solutions are particularly transformative within manufacturing, where they streamline operations, enhance product quality, ensure constant uptime, and overhaul supply chains. In this article, we’ll delve into the technological advancements redefining the manufacturing landscape. Keep reading to discover how your manufacturing business can benefit from these innovative tech solutions.

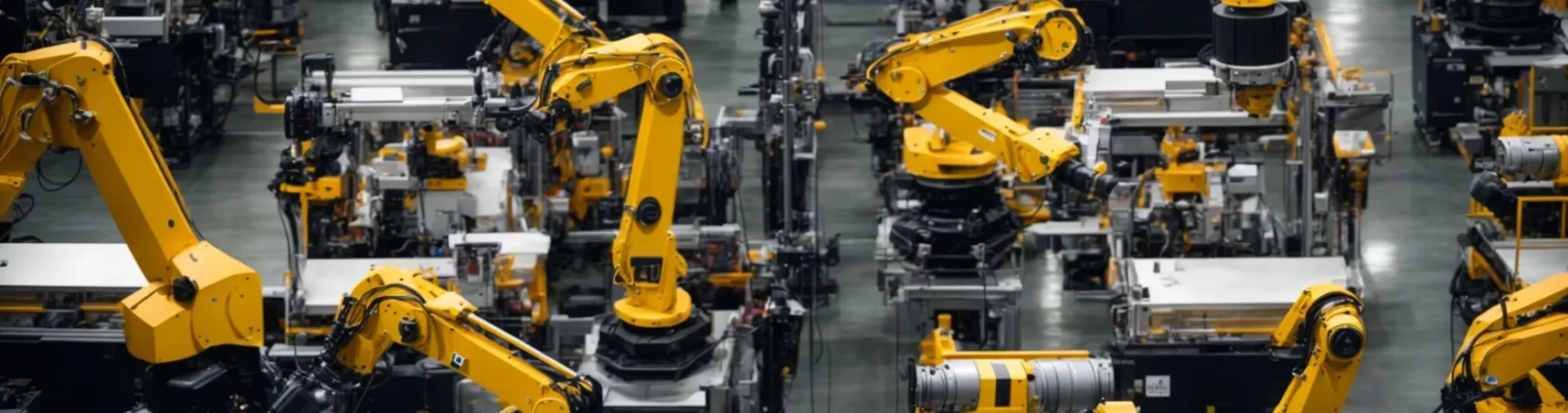

Streamlining Production Processes with Advanced Manufacturing Technologies

The advent of advanced manufacturing technologies has revolutionized production processes. Automation and robotics have enabled factories to increase output while maintaining precision and consistency. In industries with intricate assembly lines, robotics provide a level of accuracy that is difficult for human workers to replicate, reducing the occurrence of errors and the costs associated with them.

Moreover, integrating enterprise resource planning software into manufacturing ecosystems has streamlined operations by providing a unified platform for resource management. This enables businesses to monitor production schedules, inventory levels, and supply chain activities, ensuring a smooth workflow. Through efficient data management, these systems also facilitate informed decision-making.

Incorporating digital twins—virtual replicas of physical assets or systems—into manufacturing allows companies to run simulations and identify potential issues before they manifest on the actual production floor. This technology serves as a powerful tool for foreseeing the impacts of changes in design, material, or process on the product’s final quality and functionality.

Finally, additive manufacturing, more commonly known as 3D printing, is shifting the production paradigm. It allows for the creation of complex geometries that are difficult or impossible to achieve with traditional methods. It has also made it possible to fabricate production tools on demand, reducing the time and expense associated with conventional tooling.

Leveraging SEO for Increased Business Opportunities

Search Engine Optimization (SEO) has emerged as a transformative force for the manufacturing sector. It offers businesses the opportunity to enhance visibility and drive targeted traffic. By leveraging SEO, manufacturers can optimize their websites to rank higher in search engine results pages, making it easier for potential clients to discover their products and services.

A resource like OTTO SEO by Search Atlas is crucial, as many companies are now turning to online research before making purchasing decisions. Through strategic keyword integration, quality content creation, and technical optimizations, manufacturers can effectively position themselves as industry leaders while ensuring they meet the specific needs of their target audience.

SEO can help facilitate organic traffic growth and foster deeper customer engagement. By creating informative and relevant content that addresses common pain points or industry trends, manufacturers can establish their authority in the field. This educational approach not only builds trust with potential clients but also encourages return visits and increases conversion rates.

As the significance of a strong online presence continues to rise, embracing SEO strategies allows manufacturing businesses to stay competitive, adapt to market demands, and ultimately revolutionize their approach to marketing and customer acquisition in the digital age.

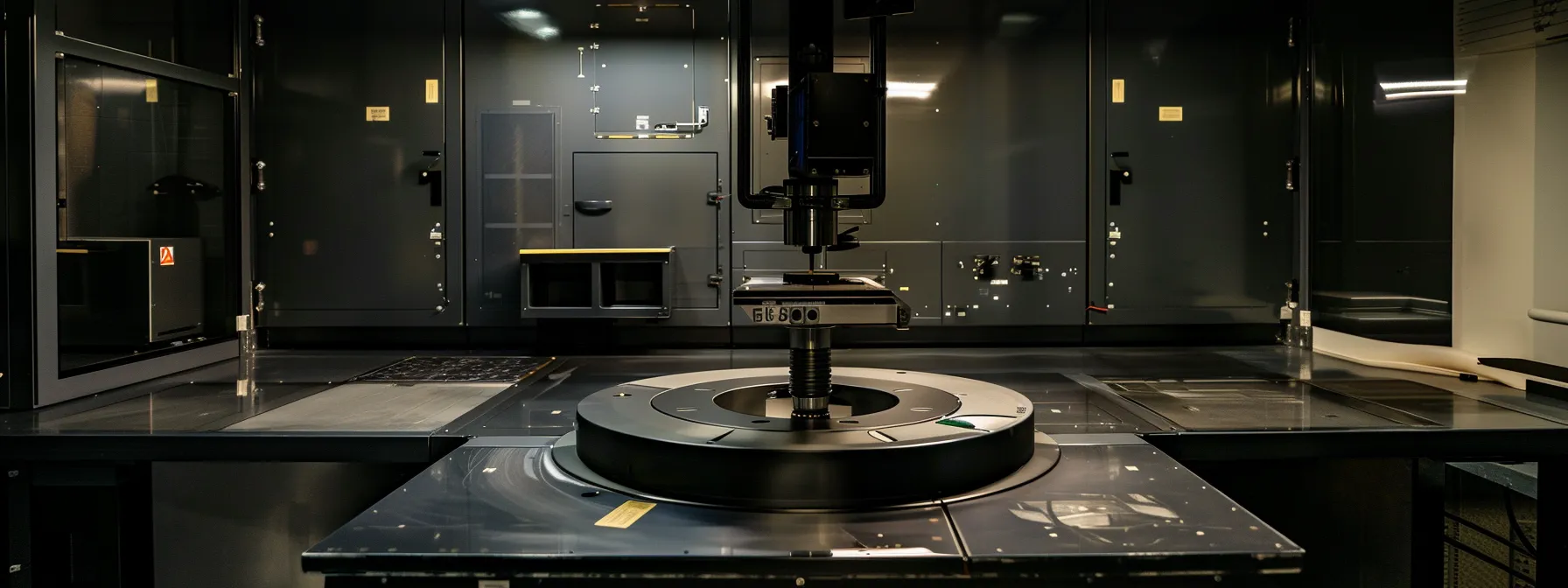

Enhancing Quality Control through Machine Learning and AI

Machine learning and AI are at the forefront of quality control innovations in manufacturing. These technologies can predict and detect defects in real time during the manufacturing process, empowering businesses to address issues promptly. AI-driven visual inspection systems, equipped with high-resolution cameras and sophisticated algorithms, can identify even the most minute imperfections at speeds far beyond human capability.

Artificial intelligence can also aggregate historical data to learn from previous inspection results, enhancing its ability to detect anomalies and refine its accuracy over time. This continual learning process is vital in maintaining the highest quality standards, particularly in industries where precision is paramount.

Beyond mere defect detection, AI systems can also analyze patterns of quality issues to identify root causes. By understanding the conditions under which defects occur, manufacturers can take proactive steps to eliminate the sources of quality problems rather than simply addressing their symptoms.

Integrating AI with other technologies, such as the Internet of Things (IoT), further amplifies its capabilities. For example, connected sensors on production equipment can feed real-time data to AI systems, enabling them to anticipate maintenance needs and prevent potential malfunctions that could compromise product quality.

Altogether, these technological solutions provide a robust framework for modernizing and advancing manufacturing businesses. From refining production practices to optimizing web presences, technology empowers manufacturers to stay competitive in an increasingly digitized world. Overall, the intelligent application of these tools can lead to substantial improvements in efficiency, quality, and business operations, cementing the path to a smarter, more prosperous industrial future.